Best Roofing Materials for Winter Springs Tuskawilla Neighborhood During Mardi Gras Season Events

Best Roofing Materials in Winter Springs FL for Tuskawilla Homes During Mardi Gras Season Events Springtime in Winter Springs means

Expert advice on roof replacement, repair, and storm protection for Central Florida homeowners

Best Roofing Materials in Winter Springs FL for Tuskawilla Homes During Mardi Gras Season Events Springtime in Winter Springs means

5 Best Roofing Companies in Deltona, FL (2026 Guide) Table of Contents If you are looking for roofing companies in

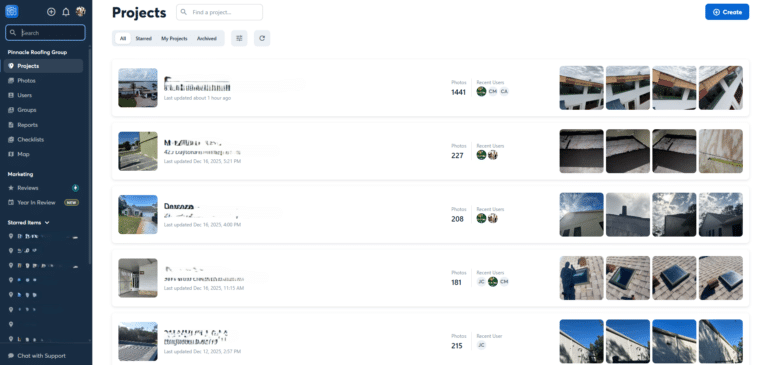

The Pinnacle Total Roofing System™: Why Central Florida’s Smartest Homeowners Choose a Complete, Certified Roof Replacement Published: February 12, 2026

The Future of Roofing: Cool Roofs, Solar Shingles, and What’s Coming With Your Next New Roof Roofing isn’t what it

The Truth About Peel-and-Stick Underlayment: Why It MUST Be Applied Directly to Decking to Count as a Secondary Water Barrier

Warranty Registration: Protecting Your Roof Long After Installation A roof replacement is one of the biggest investments you’ll make in

Cleanup & Walkthrough: How a Roofing Contractor Finishes Strong After Your Roof Replacement A roof replacement is a big project.

Daily Updates During a Roof Replacement: Why Communication Matters If you’ve ever had work done on your home, you know

Roof System Installation & Repair: Why Quality Materials and Certified Crews Matter for Your Roof Replacement When it comes to

Property Protection During a Roof Replacement: How a Professional Roofer Keeps Your Home Safe One of the biggest worries homeowners